ProtectaFlex Detect: the next generation system

Chemical industry, industrial or municipal water treatment, our systems are designed to meet the highest requirements; thus improving the safety of industrial sites, human presence, environmental conservation, and integrating Industry 4.0.

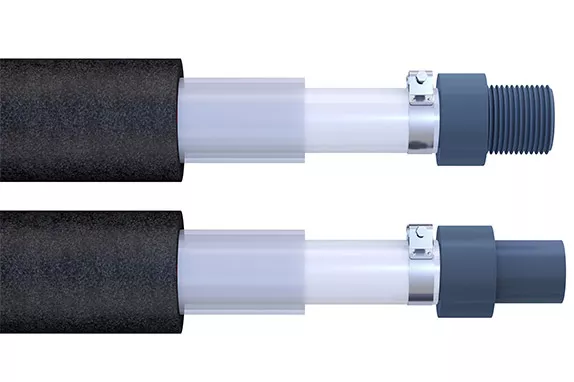

Specifically designed for the transport of chemical fluids, the next generation ProtectaFlex system has been developed to limit the impact of effluents on our environment. This double-sleeve solution is a double-walled piping system; the primary pipe in PVC, PE, or PTFE is thus confined in a second reinforced PU pipe of larger diameter, allowing for strong pressure resistance.

ProtectaFlex is the only flexible, complete, and guaranteed double-sleeve solution. This system, composed of pipes and fittings from Ø6 to Ø50, offers unparalleled chemical resistance thanks to a wide choice of materials.

Any fluid that penetrates the interstice is immediately detected at the end of the pipe by a sensor placed in a containment tank; the liquid propagates by capillarity, so there are no routing constraints (low points) as with a rigid system.

In addition to its easy installation and reduced labor costs, its innovative technology ensures a high level of reliability, limiting the risks of human damage, material damage, or environmental pollution.

Physical and Mechanical Characteristics

Standard applications

Primary Coating: PVCR or PELD

- DN 6 to 50

- Transparent PU Outer Sheath

- UV Resistance

- Fire Classification: UL94, V2 and HB

- Operating Temperature: -20°C to +55°C

- Burst Pressure: see the curve below

Extreme conditions

Primary Coating: PTFE

- DN 6 to 25

- Transparent PU Outer Sheath

- UV Resistance

- Service Temperature: -70°C to +150°C

- Fire Classification: UL94, V2 and HB

- Burst Pressure: 15 to 40 bar depending on the diameter

ProtectaFlex Detect by Aliaxis, Flexibility in Double Coating to Ensure Safe Fluid Transport

Aliaxis presents the Double Containment Solution ProtectaFlex Detect. Specifically designed to safely transport all chemical fluids, this next-generation system has been developed to help you preserve the environment by limiting the impact of effluents, while evolving towards Industry 4.0.

Lightweight, flexible, and economical, ProtectaFlex is the only double-sleeve solution suitable for small diameters from 6 to 50 mm and the most comprehensive to cover an entire industrial site. The primary pipe in PVC, PE, or PTFE is thus confined in a second reinforced PU pipe of larger diameter, allowing for strong pressure resistance.

Easy and quick to install, the double-walled piping system of ProtectaFlex can be connected to a safety system and ensures continuous integrated detection in case of leakage. Choosing Aliaxis means ensuring an optimal level of safety for fluid transport and the effectiveness of complete ranges with reduced installation and maintenance costs. ProtectaFlex by Aliaxis, flexibility for safe fluid transport.

Flexible double containment piping system

ProtectaFlex Detect

Material in Contact with the Fluid: PELD, PVCR o PTFE.

PVC-U Fittings

Various male fitting solutions are available for gluing or screwing.

Download

Contact the expert

get_app

get_app

get_app

get_app