Why is it important to avoid grease accumulation in the implant?

Grease accumulations in systems can cause many problems, so installing a grease degreaser or grease separator is important to safeguard:

1. Wastewater piping systems.

Accumulation of deposits of grease, oil, grease (also known as FOG), and food residues can cause buildup, clogging, sewer corrosion, and unpleasant odors, causing extensive damage to wastewater systems, and consequent additional costs for maintenance and restoration.2. Wastewater treatment plants.

Grease interception is critical to avoid organic overloads that interfere in subsequent treatment steps, the secondary treatments.

3. The environment

These grease interceptors prevent water with contaminant loads too high to be broken down in downstream biological treatment stages.

Regulations governing in water treatment in many countries often make grease interceptors mandatory in certain settings.

Conscientious management of graywater from civil, commercial and industrial sources helps prevent pollution of land and groundwater and helps preserve water, our planet's most precious asset.

Aliaxis' commitment to environmental protection is evidenced by offering a full range of plants that ensure proper treatment of wastewater and compliance with legal requirements in accordance with regional regulations.

Aliaxis' Isea-branded solutions include degreasers, septic tanks, Imhoff pits, activated sludge plants, and treatment plants with percolating filters that can be installed in civil, industrial, and commercial buildings for wastewater treatment and management.

Why install a civil, commercial and industrial sewage treatment system?

The correct management of graywater from civil, commercial and industrial sources helps prevent pollution of soils and aquifers and helps preserve water, our planet's most precious asset.

Aliaxis' commitment to environmental protection is evidenced by offering a full range of plants that ensure proper treatment of wastewater and compliance with legal requirements in accordance with regional regulations.

Aliaxis' Isea-branded solutions include degreasers, septic tanks, Imhoff pits, activated sludge plants, and treatment plants with percolating filters that can be installed in civil, industrial, and commercial buildings for wastewater treatment and management.

What is a degreaser or grease separator?

Grease separators are used for the pretreatment of water coming from civil buildings (kitchens, washing machines, sinks, showers, and so on) or from catering and food processing activities (hotels, restaurants, canteens, etc.) before delivery to the public sewer system or upstream of a suitable treatment plant (activated sludge, sub-irrigation, percolating filter, and so on).

Aliaxis offers a specific product portfolio in the field of wastewater treatment, the Isea division designs and manufactures innovative solutions to provide high treatment efficiency , to meet the specific needs of Customers.

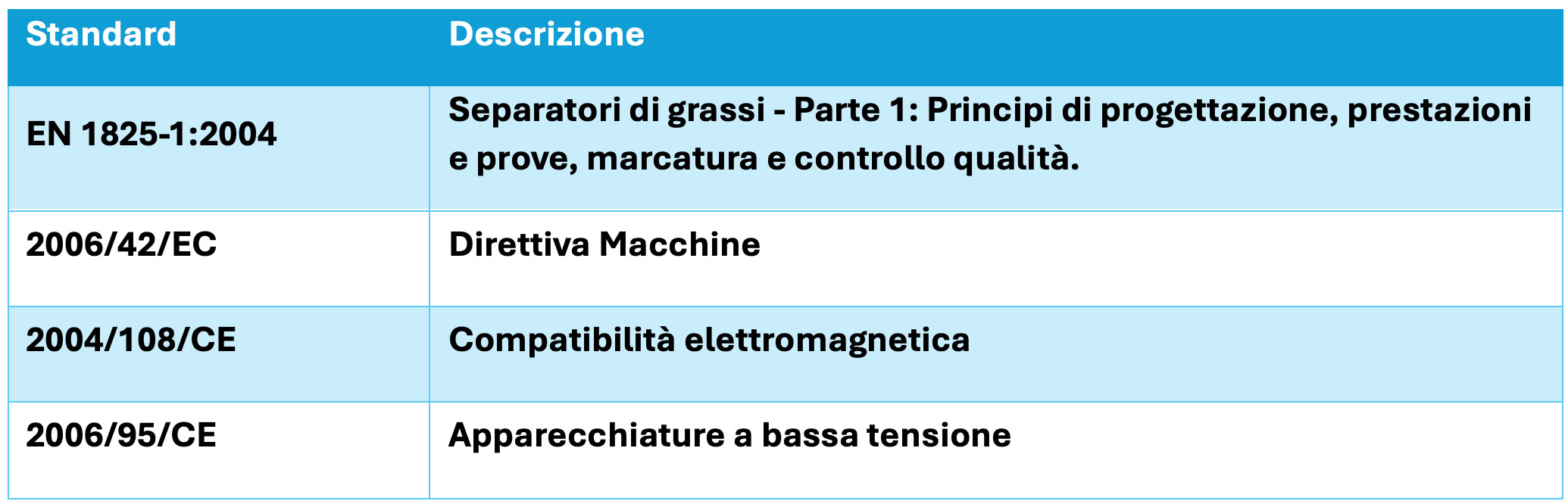

Isea brand grease separators or interceptors are manufactured in Italy, meet European standards and carry the CE mark.

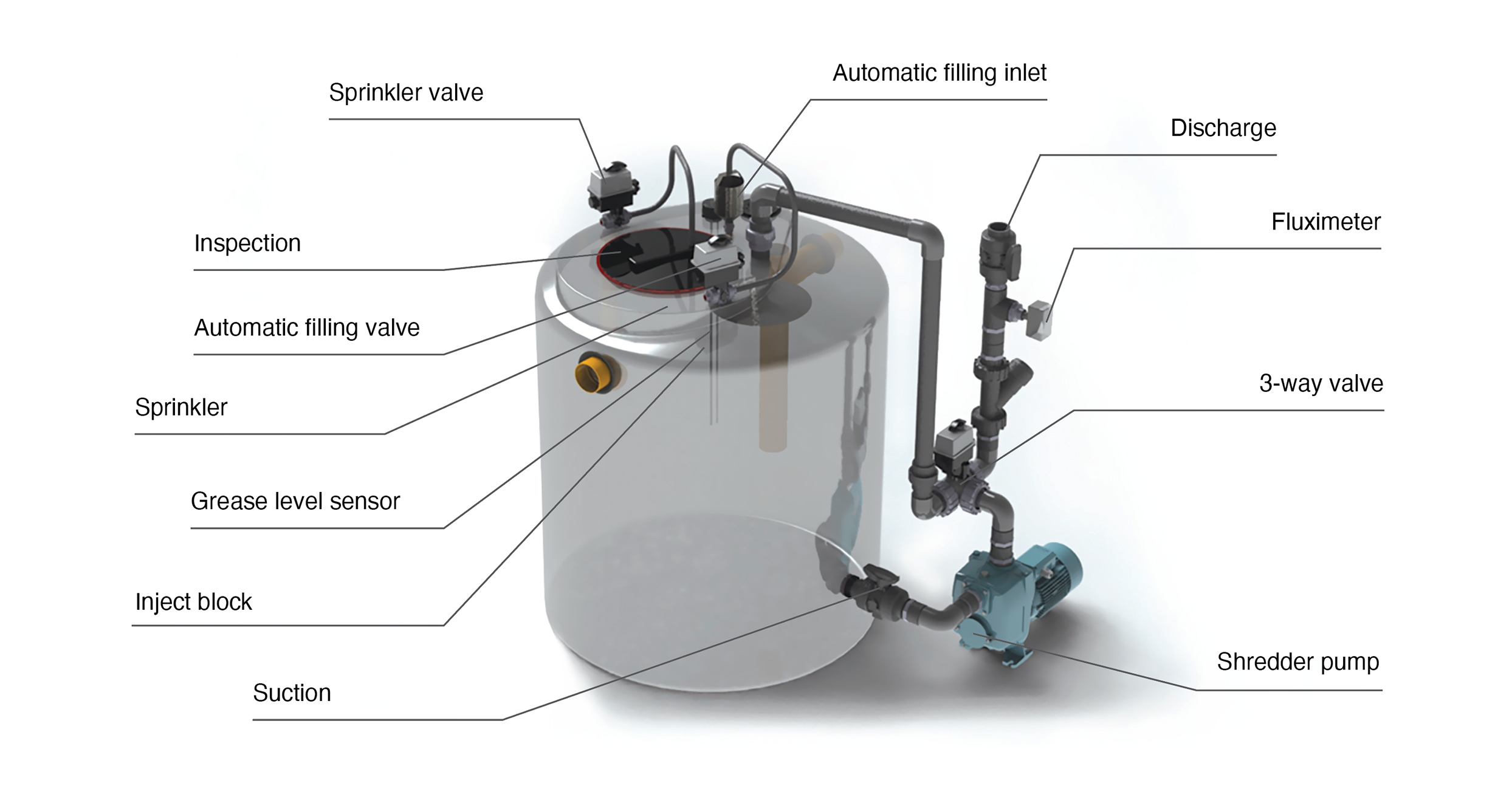

How does a degreaser work?

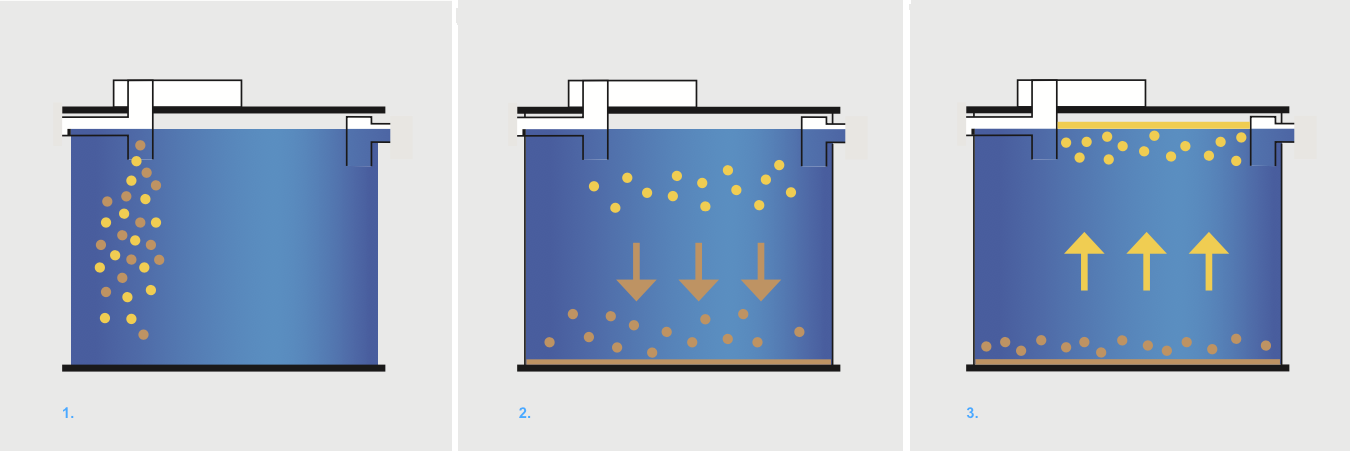

A grease interceptor exploits the principle of gravity separation: grease separation is a physical process of removing all fatty and oily substances, which have a lower specific gravity than the effluent, typical of effluent from kitchens, restaurants, or canteens.

Inside the grease condensate tank, substances contained in the effluent such as water, grease and dirt particles (sludge) separate due to their different densities.

The grease, oil and fat (whose density is 10-15% lower than water) float toward the top of the separator, while the heavier sludge settles to the bottom of the separator.

Treated graywater exits through a selective outlet cleaned of pollutants that remain trapped in the degreaser.

Once the degreaser is full, the grease, oils, and sludge are disposed of by a purge car that transports them to a plant for final treatment.

The new Self Clean automatic degreaser is designed for specific uses in Hotellerie-Restaurant-Café

The new HO.RE.CA self cleaning degreaser is available in four models:

Self Clean - Elite

The Elite version of the Self Clean degreasers is a fully automated plant; cleaning operations take place automatically. The plant is equipped with control logic and can be interfaced with external BMS systems.

This option is the ideal solution for those who need total automation in terms of operation and maintenance, without direct operator intervention, such as hotel chains with restaurants.

A customized cleaning plant with higher pressure can also be made upon request.

Self-Cleaning - Plus

The Plus version of Self Clean degreasers offers an automatic alarm, flushing and filling system. The emptying operation must be carried out by means of a vacuum cleaner.

→ Recommended for food service applications, especially in situations where maintenance services are available for emptying and cleaning equipment. The equipment is also designed to support the integration of remote sensors.

Pro Option

The Pro version of Self Clean degreasers offers a basic system that provides automatic filling and grease alarm signaling and fully manual flushing and emptying.

→ The system is designed to offer a first level of automation, while maintenance operations are the responsibility of the customer. Suitable for the most qualified residential types.

Basic Option

The Basic version of the Self Clean degreasers offers a static grease interceptor: all operations are performed manually by an operator at regular check intervals.

→ The static grease interceptor alone provides for totally customer-responsible operation. More suitable for residential settings with low separation rates.

The advantage of an automatic degreaser

The grease separators of the Horeca series, are designed for specific application in professional kitchens of restaurants, canteens or fast food restaurants.

Thanks to their automated emptying and cleaning system, they allow periodic cleaning operations to be drastically reduced.

During the emptying operation, which is done directly from the outside via self-purging, the operational impact is minimized, and the odor problems typical of these operations are greatly contained.

All this greatly reduces the interruption of food service, minimizes the overall impact of the operation, and allows for very fast recovery times.

Regulatory requirements

The ISEA family of degreasers

Grease interceptors offer a practical and efficient solution for many wastewater treatment applications.

Their ease of access, cost-effectiveness and flexibility make them an excellent choice for companies looking for a reliable and efficient wastewater treatment plant.

Due to their design, they require less excavation and installation work, reducing both installation and maintenance costs.

Grease interceptors are highly flexible and can be easily relocated as needed.

AUTOMATIC DEGRASSER HO.RE.CA.

Grease interceptor for professional and industrial kitchens, Hotellerie, Restaurant and Café.

FAMILY - TOP - PUBLIC DE GRASSER (equipped with vent)

One-piece polyethylene degreaser used as pretreatment of gray water of civil origin.

PC DEGRASSER (equipped with vent).

Monoblock polyethylene degreaser, used as pretreatment of gray water of civil origin.

DEGRASSER PLUS (Ex. Emilia Romagna / Umbria) (equipped with vent),

Monobloc polyethylene degreaser, used as pretreatment of gray water, complying with regulations in the Emilia Romagna Region and the Umbria Region.

DEGRASSER SL (equipped with vent).

Under-sink degreaser made of one-piece polyethylene, for installation in confined spaces, for intercepting grease in small commercial activities such as professional kitchens, delicatessens, canteens.

Benefits of ISEA solutions

- Ready for installation

- Compliant with regulations

- Ease of operation and maintenance

Request information

Download