Aliaxis supplies a complete range of non-return valves for sewers of which OTTIMA represents the most technologically advanced solution

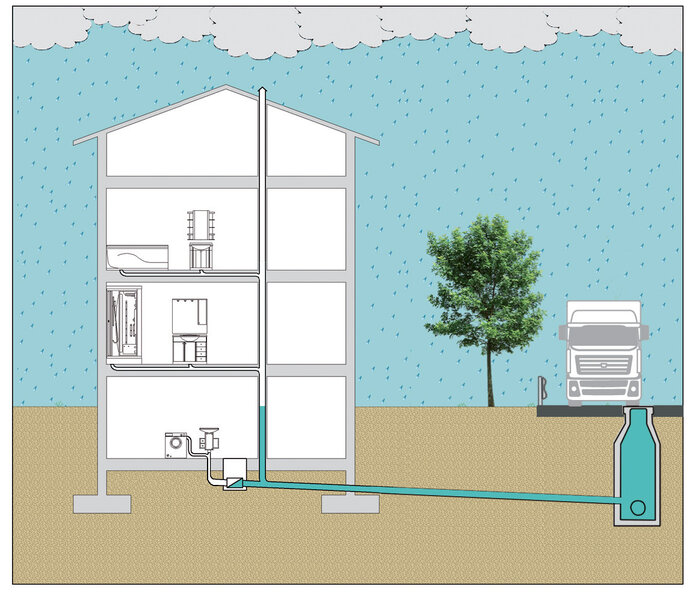

The non-return valve must be installed in the drainage pipes and allows the normal flow of water into the public sewer system, preventing its backflow.

If the sewers are overloaded, there is often a risk of flooding of garages, cellars and basement rooms.

Installing an anti-backflow valve protects the home from the return of water from the sewer and avoids economically significant damage

Its use is particularly indicated in cases of:

- Basement rooms

- Areas adjacent to rivers, lakes, sea

- In areas subject to heavy rainfall and with dated ducts

- In case of frequent overloads of sewer systems due to undersized networks

- Danger of overloading of sewers in areas of rapid urban growth

- In the presence of pumping stations along the municipal sewerage network

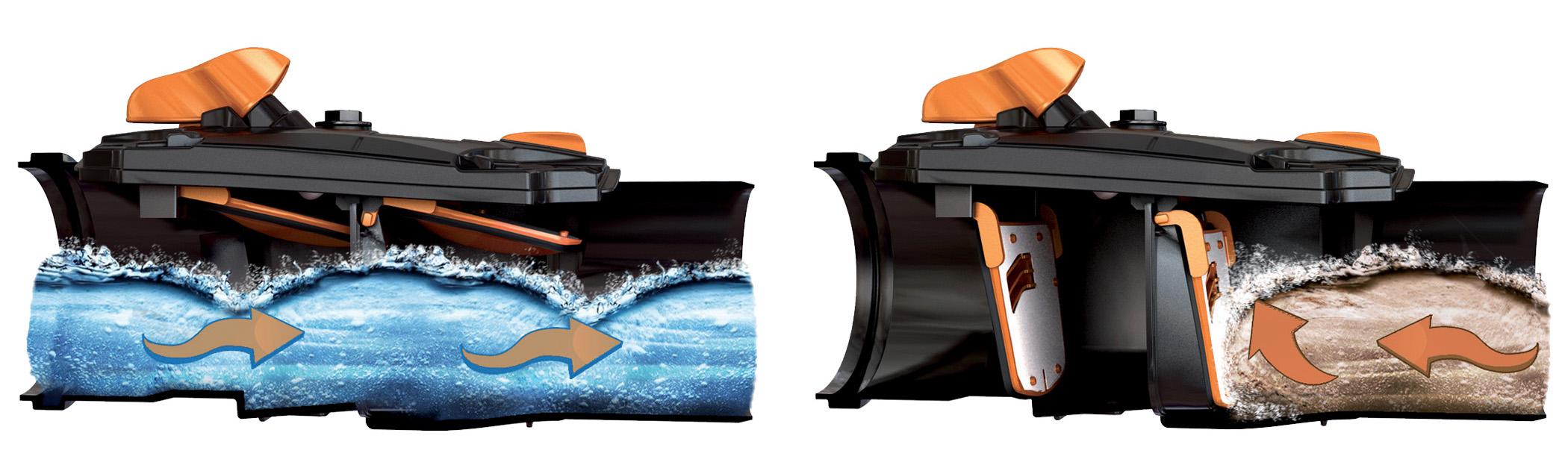

Operation

Normal discharge

Anti-backflow activated

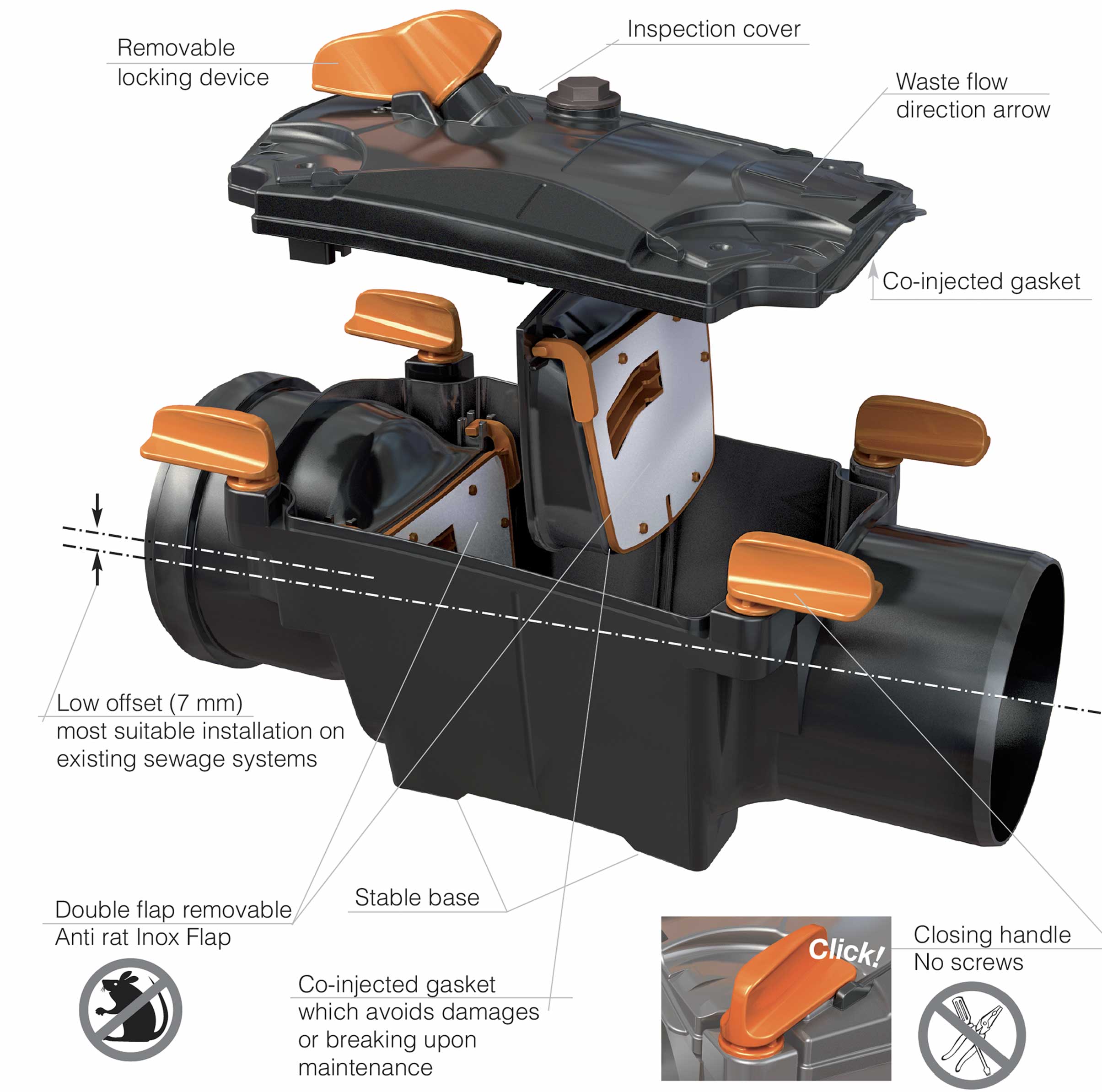

The OTTIMA anti-return valve

The OTTIMA anti-return valve can be equipped with a double tilting stainless steel plate which allows the normal flow of water out of the building towards the sewer, but which, in the event of backflow, closes mechanically with the push of the water.

The double stainless steel plate also blocks mice and rodents, which otherwise would be able to climb back into the house through the sewer pipes.

Technical features:

- Removable locking handle

- Flow direction arrow on the lid

- Bi-injected gasket: integral with the lid, it does not get lost during inspection and cleaning operations

- Manual opening lever

- Stable support base

- Double stainless steel plate as standard (TYPE 2 version)

- Can be installed on existing systems

Materials:

- Body and cover in black PVC

- Handle and opening levers in orange fibreglass-reinforced nylon

- PP plate coated with anti-rodent stainless steel and with bi-injected gaskets

The materials with which the body and the various components of the valve are made avoid corrosion, oxidation and rust problems.

Where to place the non-return valve?

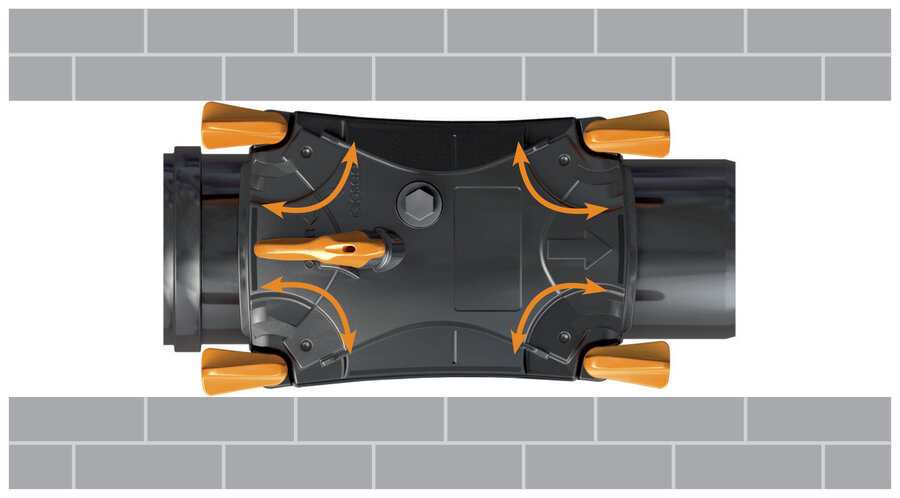

The OTTIMA anti-return valve is installed in an accessible and inspectable well.

The anti-return valve should be included in the design and sizing phase of the building's drainage system, but if it was not done during the construction phase, it can easily be done afterwards.

The advantages of the OTTIMA anti-return valve

The OTTIMA Valve is easily inspected, does not require tools to open, the handles are quick release. Opening the valve is easy

access even in small spaces. For correct operation, an inspection once a year is recommended.

Types of anti-return valves OTTIMA

A safe and reliable underground drainage system is essential to protect both the environment and communities. To meet this need, Aliaxis offers a complete range of sustainable and long-lasting solutions.

The OTTIMA anti-backflow valve must be installed in the drainage pipes and allows the normal flow of water into the public sewer, preventing its backflow.

The OTTIMA non-return valve is available in plug-in, lip seal, M/F glued and male/male versions with 1 and 2 plates.

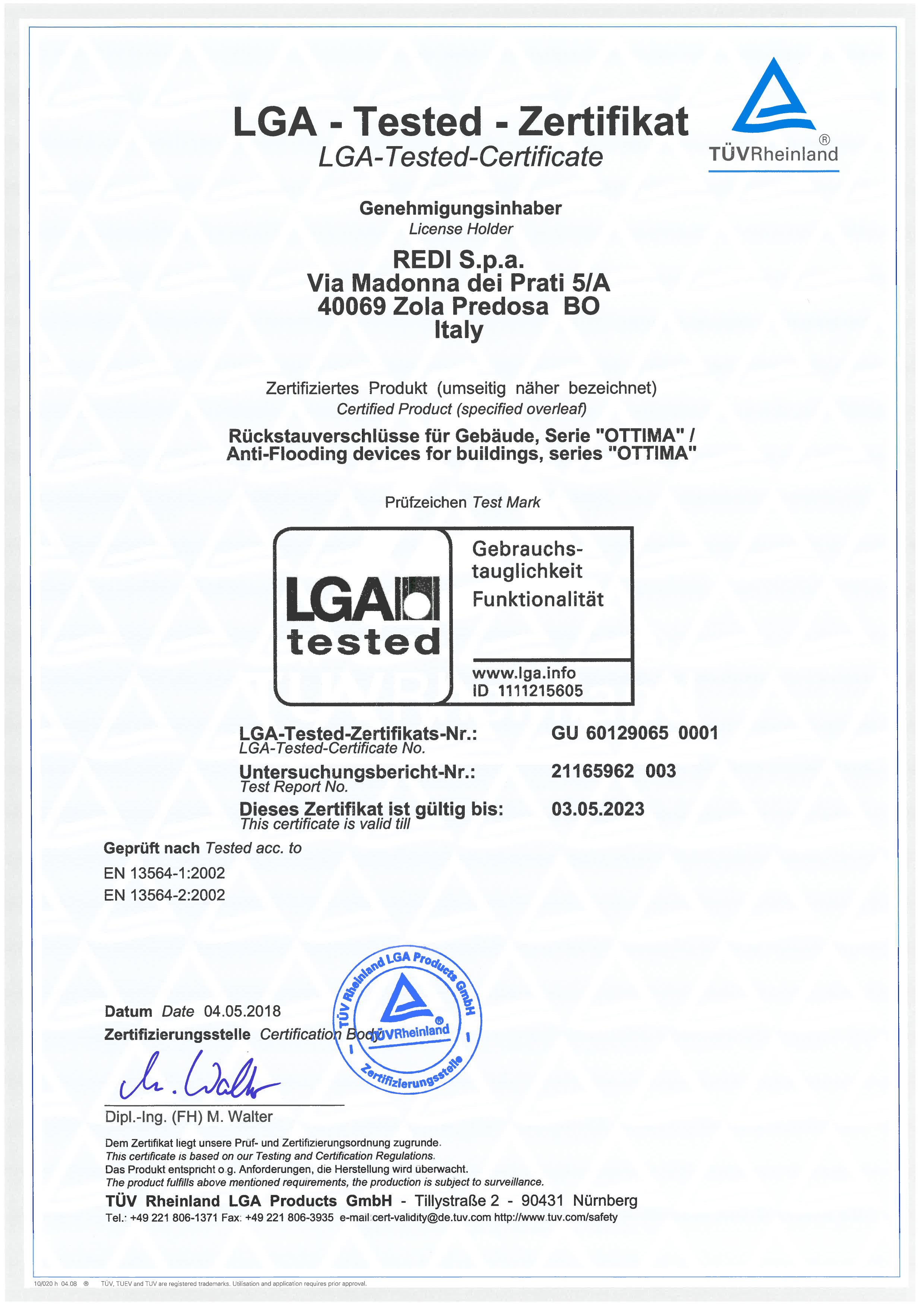

The device is marked and complies with the EN 13564 standard, guaranteed by an authorized institute.

The body and lid are made of injection molded rigid PVC.

The dimensions of the joints comply with EN 1401 and EN 1329. The joint system can be of the gluing or joint type with sealing gasket, the joint gaskets are certified according to the EN 681 standard.

The inspection cover is removable and equipped with a lever release system, the hydraulic seal is integral with the cover.

The plates are removable, equipped with an integral, non-removable hydraulic seal. The valve is built in compliance with the design, functional and maintenance requirements of exhaust systems, according to EN 12056.

Anti-return valve OTTIMA TYPE 2

- 2 plates

- plug-in with lip seal

- glued

- M/F

- Male/male

Anti-return valve OTTIMA TYPE 1

- 1 plate

- plug-in with lip seal

- glued

- M/F

- Male/male

Flooded cellar? Who pays the damages?

In the event of an exceptional atmospheric event such as a storm or a water bomb, it may happen that the sewers are not able to dispose of the water. In this case, however, the Civil Liability of the Municipality for any damage caused to the home is to be considered excluded: "the exceptional nature of the atmospheric phenomenon was such as to interrupt the causal link between the negligent conduct attributable to the entity and the damage suffered ( Order of the Supreme Court n.3764/2014)". This means that the municipality, as the owner of the sewer system, does not have to compensate for the damage caused to the property.

More and more people are turning to insurance companies to protect themselves from this type of damage. Often the contract provides coverage for the general risk of flooding, but does not specifically cover backflow from the sewer. The cost of damage can be very significant and insurance can only compensate for damage.

An anti-backflow valve, correctly installed and regularly maintained, eliminates the possibility of backflow and therefore prevents damage from occurring. For further information:“Security: risks, responsibilities and legal disputes”.

We have achieved high levels of knowledge in the selection of the materials that make up our products, in the design and production, as well as in the definition of the simplest, most reliable and long-lasting installation systems.

Thanks to the experiences of its companies, the Aliaxis Group is able to offer high quality products to guarantee maximum safety.

Requirements and mandatory certifications of non-return valves

The anti-return valves are certified by the “TÜV Rheinland LGA” Institute in Würzburg (D), according to the European standard EN 13564.

The certified sewer anti-backflow valve guarantees the following performances:

- Regular flow guaranteed by the opening of the plate even in the presence of minimal pressures (50 mm of water column equal to 0.005 bar).

- Non-deformability and resistance of the product after 600 test cycles at variable temperatures (60 seconds at 75°C / 60 seconds at 15°C).

- Effectiveness of the anti-backflow device subjected to 35 backflow cycles with duration varying from 5 to 10 minutes and pressure from 0.01 to 0.5 bar (equal to 5 meters of water column).

- Resistance and hydraulic seal of the entire valve body subjected to a pressure of 5 meters of water column equal to 0.5 bar.

- Conformity of the couplings to the dimensions established by the EN 1401 and EN 1329 standards.

- Optimal sizing and free operation of the moving parts to avoid the risk of jamming during the opening/closing movements.

The Aliaxis Anti-Backflow Valves are marked as established in Annex ZA of the harmonized European standard EN 13564-1:2002, and in compliance with the European Directive 89/106/EEC of 21 December/1988 on construction products.

get_app

get_app