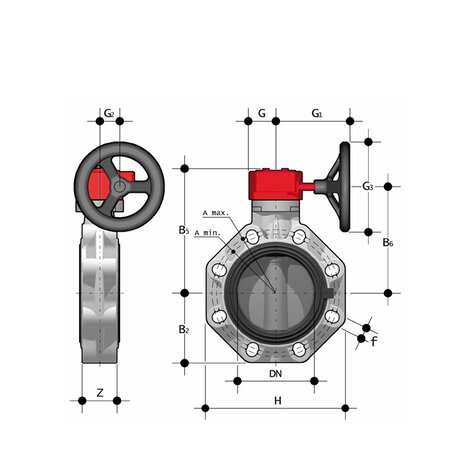

FKOV/RM - Butterfly valve DN 40:400

Gearbox operated butterfly valve.

The FK is a butterfly valve for shutting off or regulating flow, with structural characteristics that make it ideal for industrial applications requiring high performance and longterm reliability. This valve is also equipped with the customisable Labelling System.

Main features:

- Ergonomic handle in HIPVC equipped with locking and unlocking device, release, quick operation and graduated adjustment in 10 intermediate positions (DN 40÷200). The operating range, starting from the first few degrees of valve opening, also guarantees extremely low pressure drops.

- Customisable Labelling System: integrated module in the handle, made of a transparent protection plug and a customisable tag holder using the LSE set (available as an accessory). The customisation lets you identify the valve on the system according to specific needs.

- STAINLESS steel square section stem completely isolated from the fluid complying with standard ISO 5211:

- DN 40÷65: 11 mm

- DN 80÷100: 14 mm

- DN 125÷150: 17 mm

- DN 200: 22 mm

- DN 250÷400: 27 mm

- Body in polypropylene based compound reinforced with fibreglass (PP-GR) resistant to UV rays and characterised by high mechanical strength.

- Drilling pattern using oval slots that allow coupling to flanges according to numerous international standards. The special self-centring inserts in ABS supplied for DN 40÷200 guarantee the correct axial alignment of the valve during installation. For DN 250÷400 valves, the drilling pattern for the selfcentring system is of the traditional type according to DIN and ANSI standards.

- Interchangeable liner with the dual function of forming a hydraulic seal and isolating the body from the fluid.

EPDM

| Reference | d | DN | PN | A min | A max | øA | B2 | B5 | B6 | G | G1 | G2 | G3 | H | U | Z | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FKOVRM050E | 50 | 40 | 16 | 99 | 109 | - | 60 | 161 | 133 | 48 | 135 | 39 | 125 | 132 | 4 | 33 | 1974 |

| FKOAVRM814E | 14" | 350 | 7 | - | - | 476 | 280 | 438 | 390 | 88 | 361 | 80 | 300 | 530 | 12 | 129 | 34450 |

| FKOAVRM812E | ****12" | 300 | 8 | - | - | 432 | 245 | 374 | 338 | 88 | 236 | 76 | 250 | 475 | 12 | 114 | 25600 |

| FKOAVRM810E | ****10" | 250 | 10 | - | - | 362 | 210 | 317 | 281 | 88 | 236 | 76 | 250 | 405 | 12 | 114 | 18600 |

| FKOVRM400E | 400 | 400 | 6 | - | - | 515 | 306 | 438 | 390 | 88 | 361 | 80 | 300 | 594 | 16 | 169 | 42450 |

| FKOVRM355E | 355 | 350 | 7 | - | - | 460 | 280 | 438 | 390 | 88 | 361 | 80 | 300 | 530 | 16 | 129 | 34450 |

| FKOVRM315E | ***315 | 300 | 8 | - | - | 400 | 245 | 374 | 338 | 88 | 236 | 76 | 250 | 475 | 12 | 114 | 25600 |

| FKOVRM280E | ***280 | 250 | 10 | - | - | 350 | 210 | 317 | 281 | 88 | 236 | 76 | 250 | 405 | 12 | 114 | 18600 |

| FKOVRM225E | 225 - 8" | 200 | 10 | 280 | 298 | - | 161 | 287 | 256 | 65 | 204 | 60 | 200 | 323 | 8 | 71 | 9300 |

| FKOVRM160E | 160 - 6" | 150 | 10 | 230 | 242 | - | 134 | 235 | 207 | 48 | 144 | 39 | 200 | 268 | 8 | 70 | 5200 |

| FKOVRM140E | 140 - 5" | 125 | 10 | 204 | 215 | - | 120 | 222 | 194 | 48 | 144 | 39 | 200 | 240 | 8 | 64 | 4450 |

| FKOVRM110E | 110 - 4" | 100 | 10 | 165 | 190 | - | 107 | 202 | 174 | 48 | 135 | 39 | 125 | 211 | 8 | 56 | 3150 |

| FKOVRM090E | 90 - 3" | 80 | 10 | 145 | 160 | - | 93 | 188 | 160 | 48 | 135 | 39 | 125 | 185 | 12 | 49 | 2800 |

| FKOVRM075E | 75 - 2"1/2 | 65 | 10 | 128 | 144 | - | 80 | 174 | 146 | 48 | 135 | 39 | 125 | 165 | 4 | 46 | 2400 |

| FKOVRM063E | 63 | 50 | 16 | 115 | 125,2 | - | 70 | 167 | 139 | 48 | 135 | 39 | 125 | 147 | 4 | 43 | 2154 |

| FKOAVRM816E | 16" | 400 | 6 | - | - | 540 | 306 | 438 | 390 | 88 | 361 | 80 | 300 | 594 | 16 | 169 | 42450 |

FKM

| Reference | d | DN | PN | A min | A max | øA | B2 | B5 | B6 | G | G1 | G2 | G3 | H | U | Z | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FKOVRM050F | 50 | 40 | 16 | 99 | 109 | - | 60 | 161 | 133 | 48 | 135 | 39 | 125 | 132 | 4 | 33 | 1974 |

| FKOAVRM814F | 14" | 350 | 7 | - | - | 476 | 280 | 438 | 390 | 88 | 361 | 80 | 300 | 530 | 12 | 129 | 34450 |

| FKOAVRM812F | ****12" | 300 | 8 | - | - | 432 | 245 | 374 | 338 | 88 | 236 | 76 | 250 | 475 | 12 | 114 | 25600 |

| FKOAVRM810F | ****10" | 250 | 10 | - | - | 362 | 210 | 317 | 281 | 88 | 236 | 76 | 250 | 405 | 12 | 114 | 18600 |

| FKOVRM400F | 400 | 400 | 6 | - | - | 515 | 306 | 438 | 390 | 88 | 361 | 80 | 300 | 594 | 16 | 169 | 42450 |

| FKOVRM355F | 355 | 350 | 7 | - | - | 460 | 280 | 438 | 390 | 88 | 361 | 80 | 300 | 530 | 16 | 129 | 34450 |

| FKOVRM315F | ***315 | 300 | 8 | - | - | 400 | 245 | 374 | 338 | 88 | 236 | 76 | 250 | 475 | 12 | 114 | 25600 |

| FKOVRM280F | ***280 | 250 | 10 | - | - | 350 | 210 | 317 | 281 | 88 | 236 | 76 | 250 | 405 | 12 | 114 | 18600 |

| FKOVRM225F | 225 - 8" | 200 | 10 | 280 | 298 | - | 161 | 287 | 256 | 65 | 204 | 60 | 200 | 323 | 8 | 71 | 9300 |

| FKOVRM160F | 160 - 6" | 150 | 10 | 230 | 242 | - | 134 | 235 | 207 | 48 | 144 | 39 | 200 | 268 | 8 | 70 | 5200 |

| FKOVRM140F | 140 - 5" | 125 | 10 | 204 | 215 | - | 120 | 222 | 194 | 48 | 144 | 39 | 200 | 240 | 8 | 64 | 4450 |

| FKOVRM110F | 110 - 4" | 100 | 10 | 165 | 190 | - | 107 | 202 | 174 | 48 | 135 | 39 | 125 | 211 | 8 | 56 | 3150 |

| FKOVRM090F | 90 - 3" | 80 | 10 | 145 | 160 | - | 93 | 188 | 160 | 48 | 135 | 39 | 125 | 185 | 12 | 49 | 2800 |

| FKOVRM075F | 75 - 2"1/2 | 65 | 10 | 128 | 144 | - | 80 | 174 | 146 | 48 | 135 | 39 | 125 | 165 | 4 | 46 | 2400 |

| FKOVRM063F | 63 | 50 | 16 | 115 | 125,2 | - | 70 | 167 | 139 | 48 | 135 | 39 | 125 | 147 | 4 | 43 | 2154 |

| FKOAVRM816F | 16" | 400 | 6 | - | - | 540 | 306 | 438 | 390 | 88 | 361 | 80 | 300 | 594 | 16 | 169 | 42450 |

FKM

| Reference | d | DN | PN | A min | A max | øA | B2 | B5 | B6 | G | G1 | G2 | G3 | H | U | Z | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FKOVRM050F0SF | 50 | 40 | 16 | 99 | 109 | - | 60 | 161 | 133 | 48 | 135 | 39 | 125 | 132 | 4 | 33 | 1974 |

| FKOVRM063F0SF | 63 | 50 | 16 | 115 | 125,2 | - | 70 | 167 | 139 | 48 | 135 | 39 | 125 | 147 | 4 | 43 | 2154 |

| FKOVRM075F0SF | 75 - 2"1/2 | 65 | 10 | 128 | 144 | - | 80 | 174 | 146 | 48 | 135 | 39 | 125 | 165 | 4 | 46 | 2400 |

| FKOVRM090F0SF | 90 - 3" | 80 | 10 | 145 | 160 | - | 93 | 188 | 160 | 48 | 135 | 39 | 125 | 185 | 12 | 49 | 2800 |

| FKOVRM110F0SF | 110 - 4" | 100 | 10 | 165 | 190 | - | 107 | 202 | 174 | 48 | 135 | 39 | 125 | 211 | 8 | 56 | 3150 |

| FKOVRM140F0SF | 140 - 5" | 125 | 10 | 204 | 215 | - | 120 | 222 | 194 | 48 | 144 | 39 | 200 | 240 | 8 | 64 | 4450 |

| FKOVRM160F0SF | 160 - 6" | 150 | 10 | 230 | 242 | - | 134 | 235 | 207 | 48 | 144 | 39 | 200 | 268 | 8 | 70 | 5200 |

- Interchangeable disk in PVC-U with through shaft, available in different thermoplastic materials: PP-H, PVC-C, ABS, PVDF

- Overall dimensions of the valve in accordance with standard ISO 5752 (DN 40÷200 Medium Series 25, DN 250÷ 300 Long Series 16) and DIN 3202 K2 and ISO 5752 (DN 65÷200 K2, DN 250÷300 K3)

- Can also be installed as an end line valve, bottom discharge valve or tank dump valve

- Special Lug version PN 10 fully drilled to DIN 2501 or ANSI B16.5 cl.150 with molded-in AISI 316 STAINLESS steel threaded inserts

- Valve material compatibility (PVC-U + EPDM) with water conveyance, drinking water and other food substances according to current regulations

- Possibility of installing a manual reducer or pneumatic and/or electric actuators by applying an ISO standard drilling PP-GR flanges. DN 40 ÷ 200 valve fitted with plate with rack in PP-GR. For actuated versions with flange drilled according to ISO 5211 F05, 07, F10. DN 250÷400 valve, fitted with one-piece top flange in high mechanical strength PP-GR with mounting flange for internal components drilled according to standard ISO 5211 F10 (excluding DN 350÷400), F12, F14.

- Possibility to have handle with integrated LSQT limit micro switch, even as a retrofit in existing installations

Videos

FK Butterfly Valve DN 40÷400 - EN

get_app

get_app

get_app

get_app