PVDF valves, PVDF fittings and PVDF pipe

The PVDF (polyvinylidene fluoride) material is a semi-crystalline fluorinated technopolymer containing 59% by weight of fluorine. This material is obtained through the polymerization of vinylidene fluoride and has exceptional characteristics of resistance both from a mechanical and from a physical and chemical point of view, guaranteeing excellent thermal stability performance up to temperatures of 140°C.

For the production of pipes, fittings and valves, made by extrusion and injection, the FIP PVDF line has always used PVDF resins specifically formulated for industrial applications.

PVDF material properties:

Thanks to its high purity and exceptional performances, PVDF represents the best alternative to metallic materials, finding wide use in the industrial sector (chemical, petroleum, pharmaceutical, cellulose and paper, electronic, etc.), in process and non-process plants. Among the most important properties and advantages of PVDF we can mention below.

Excellent thermal stability

The use of a vinylidene fluoride polymer, guarantees excellent resistance to corrosion and abrasion when conveying highly aggressive chemical substances. PVDF is generally inert to most inorganic acids and bases, organic acids, aromatic and aliphatic hydrocarbons, alcohols and halogenated solvents, while its use with fluorine, amines, ketones and oleum (sulfuric acid with sulfur trioxide) is not recommended.

Excellent thermal stability

PVDF is a material which maintains its characteristics unaltered in a temperature range between –40°C and +140°C. The PVDF piping system is particularly suitable for all applications where high operating temperatures, very low levels of fluid contamination and high resistance to aging from atmospheric agents and UV radiation are required. The excellent mechanical characteristics of the material remain unchanged even at high temperatures.

Fire resistant

PVDF resins guarantee excellent fire resistance without the need for flame retardants (Limit Oxygen Index, LOI=44%). In case of combustion, smoke emissions are moderate. PVDF resins are classified UL-94, class V-O.

Purity

PVDF resin is an extremely pure polymer which does not contain stabilizers, plasticizers, lubricants or flame retardants. It is, therefore, the ideal material for conveying ultra-pure water and chemicals, if the absence of contamination of the conveyed fluid is required. Since it is physiologically non-toxic, it is suitable for conveying fluids and food products.

High abrasion resistance

According to the Taber Abrasion Test (in which the weight loss of a material is measured after being exposed to the friction of an abrasive wheel for 1000 cycles), PVDF is the material with the best resistance compared to all thermoplastics (CS-10 Load 1Kg – Weight Loss /1000 Cycles = 5-10 mg.)

PVDF valves, PVDF pipe and PVDF fittings:

Systems in PVDF material (polyvinylidene fluoride) are useful for all those applications in extreme operating conditions, such as the transformation and dosing of aggressive chemicals or the regeneration and transport of concentrated acids used in industrial chemical synthesis, mining or metallurgical production processes . Some of the main international steel producers have chosen our PVDF solutions to carry out the pre-treatments for the removal of organic deposits and rust before the surface finishing phases.

In addition to offering considerable resistance, PVDF is light, installs easily and lasts a long time because, in addition to not being subject to the risk of corrosion, it offers exceptional inertness to chemical and mechanical stress. All the solutions in our portfolio ensure excellent price/performance ratio and do not require particularly complex installation and joining techniques.

ISO-UNI PVDF pipe

Pressure tube.

Pressure pipes for jointing system by butt or socket welding.

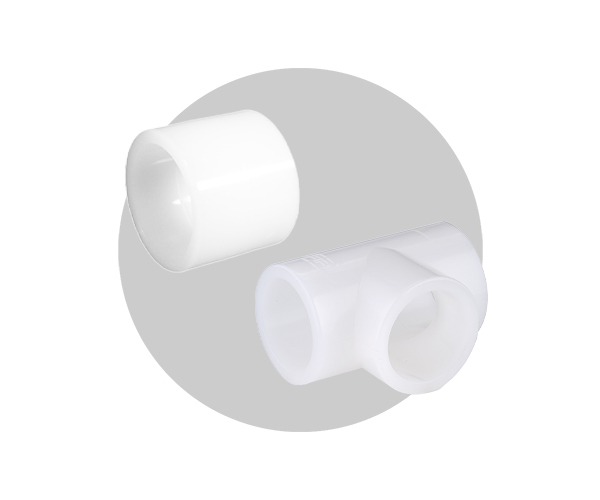

PVDF ISO-UNI fittings

Series of fittings intended for the conveyance of pressurized fluids with jointing system by means of socket hot welding.

PVDF ISO-BSP fittings

ISO-BSP through fittings.

Series of fittings intended for the conveyance of pressurized fluids with jointing system by means of threading and socket heat welding.

VKD Dual Block - PVDF VALVE

DUAL BLOCK® 2-way ball valve.

FIP has developed a two-way ball valve of the VKD DUAL BLOCK® type to introduce a high reference standard in the conception of thermoplastic valves. VKD is a radially disassembled collet ball valve that meets the most stringent requirements required in industrial applications.

VKR Dual Block -PVDF VALVE

DUAL BLOCK® regulating ball valve.

The VKR DUAL BLOCK® valve combines the high levels of reliability and safety typical of the VKD full bore ball valve with the new flow regulation function with linear type characteristic curve which meets the most stringent requirements typical of industrial applications.

SR - PVDF VALVE

Ball check valves.

The check valve SR has the function of allowing the passage of the fluid in one direction only.

FK - PVDF VALVE

Butterfly Valve.

The FK is a shut-off and regulation butterfly valve, with structural characteristics that are ideal for use in industrial applications that require high performance and reliability over time. This valve is also equipped with the customized Labeling System.

DK Dialock - PVDF VALVE

DIALOCK® 2-way diaphragm valve.

The DK DIALOCK® diaphragm valve is ideal for regulating and shutting off abrasive fluids or fluids with impurities. The new internal geometry of the body significantly increases the flow coefficient, reduces pressure drops and allows accurate adjustment over the entire poppet stroke. The DK has reduced dimensions and weight. The innovative handwheel is equipped with a patented mechanism for locking the manoeuvre, immediate and ergonomic, which allows you to lock any adjustment position reached.

CM - PDF VALVE

Compact diaphragm valve.

The CM is a manually operated diaphragm valve of reduced dimensions and particularly compact structure, ideal for use in confined spaces.

VM - PVDF VALVE

Diaphragm valve.

The VM is particularly suitable for the regulation and interception of abrasive fluids or fluids containing impurities. The handwheel control and the diaphragm seal allow precise and effective regulation and reduce the risk of water hammer to a minimum.

Do you need to make a flanged connection?

Aliaxis has designed the innovative 3+ Backing Ring which, thanks to its optimized design, combines a unique lightness with exceptional mechanical strength, ensuring a simple, safe and reliable installation.

Are you interested in the actuated versions?

Beside the manually operated versions, Aliaxis offers the actuated versions which are made using actuators compliant with current regulations and selected by FIP on the basis of their quality and reliability requirements. The efficiency of these valves, tested according to the company's quality standards, is guaranteed by the expertise and know-how that FIP dedicates to the creation of its products.

Normative requirements

The production of the PVDF lines is carried out following the highest quality standards and in full compliance with the environmental constraints imposed by the laws in force and in accordance with the ISO 14001 standard. All products are manufactured in accordance with the quality assurance system according to the ISO 9001 standard.

- ANSI B16.5 Pipe Flanges and Flange Fittings-NPS 1/2 to NPS 24 mm/inch.

- ASTM D3222 PVDF Coating and Extrusion Molding Material.

- DVS 2202-1 PVDF weld joint imperfections, characteristics, descriptions and evaluations.

- DVS 2207-15 Welding of PVDF components.

- DVS 2208-1 Thermocouple welding machines and equipment.

- EN 558-1 Industrial valves - External boundary dimensions of metallic valves for use in flanged piping systems - Part 1: Design according to PN.

- EN 1092-1 Flanges and their joints - Circular flanges for pipes, valve fittings and accessories - Part 1: Steel flanges, design according to PN.

- EN ISO 10931 Component systems (pipes, fittings and valves) in PVDF for industrial applications.

- ISO 5211 Couplings for fractional turn actuators.

- ISO 7005-1 Metal flanges; part 1: steel flanges.

- EN 14728 Imperfections in thermoplastic welds -classification.

- ISO 9624 Thermoplastic piping systems for fluids under pressure -flange adapters and loose backing flanges- Mating dimensions.

Approvals and quality marks

DVGW KTW, W270 Suitability of SOLVAY PVDF resin for microbiological tests

FDA (Food and Drug Administration - USA) Suitability of PVDF resin for contact with food

NSF (National Sanitation Foundation USA) Suitability of PVDF resin for use in contact with drinking water

EAC PVDF valves and fittings are EAC certified in accordance with Russian regulations for Safety, Hygiene and Quality

TA-Luft PVDF FIP valves have been tested and certified by MPA Stuttgart in accordance with Technical Instruction on Air Quality Control TA-Luft / VDI 2440

UKR SEPRO PVDF valves and fittings are certified in accordance with Ukrainian regulations for Safety, Hygiene and Quality

Are you interested in the actuated versions?

Download

News & Blog

Contact our industry expert